Cutting guidelines for sheet-metal

Index

Version 1.7 09/06/2023

On demand. On time.

Version 1.7 09/06/2023

| Plate thickness | ||

|---|---|---|

| Steel |

| |

| RVS |

| |

| Aluminium |

| |

| Minimum product dimensions | ||

| Plate thickness up to 5 mm |

| |

| Plate thickness 6 to 15 |

| |

| Plate thickness 20 mm |

| |

| Plate thickness 25 mm |

| |

| Maximum product dimensions | ||

| Plate thickness up to 10 mm |

| |

| Plate thickness12 mm |

| |

| Plate thickness15 mm |

| |

| Plate thickness20 mm |

| |

| Plate thickness 25 mm |

| |

| Minimum dimensions narrow strip (to prevent warping) | ||

| Length 100 to 750 mm |

| |

| Length 750 to 1500 mm |

| |

| Length from 1500 mm |

| |

| Minimum slot size with Steel and Stainless steel (also applicable to lead-in lenght) | ||

|---|---|---|

| Plate thickness up to 2 mm |

| |

| Plate thickness 2,5 to 15 mm |

| |

| Plate thickness 20 and 25 mm |

| |

| Minimum slot size with Aluminium (also applicable to lead-in lenght) | ||

| Plate thickness up to 2 mm |

| |

| Plate thickness 2,5 mm |

| |

| Plate thickness 3 mm |

| |

| Plate thickness 4 mm |

| |

| Plate thickness 5 mm |

| |

| Plate thickness 6 mm |

| |

| Plate thickness 8 mm |

| |

| Plate thickness 10 mm |

| |

| Minimum hole / dam size with Steel ø nitrogen | ø oxygen | ||

|---|---|---|---|

| Plate thickness 0,8 to 1 mm |

| ||

| Plate thickness 1,25 to 1,5 mm |

|

| |

| Plate thickness 2 mm |

|

| |

| Plate thickness 2,5 mm |

| ||

| Plate thickness 3 mm |

|

| |

| Plate thickness 4 mm |

|

| |

| Plate thickness 5 mm |

|

| |

| Plate thickness 6 mm |

|

| |

| Plate thickness 8 mm |

|

| |

| Plate thickness 10 to 15 mm |

| ||

| Plate thickness 20 mm |

| ||

| Plate thickness 25 mm |

| ||

| Minimum hole / dam size with RVS ø | ||

|---|---|---|

| Plate thickness 0,5 to 1 mm |

| |

| Plate thickness1,25 to 1,5 mm |

| |

| Plate thickness 2 mm |

| |

| Plate thickness 2,5 mm |

| |

| Plate thickness 3 mm |

| |

| Plate thickness 4 mm |

| |

| Plate thickness 5 mm |

| |

| Plate thickness 6 mm |

| |

| Plate thickness 8 to 12 mm |

| |

| Plate thickness 15 mm |

| |

| Plate thickness 20 mm |

| |

| Minimum hole / dam size with Aluminium ø | ||

| Plate thickness 1 mm |

| |

| Plate thickness 1,2 to 1,5 mm |

| |

| Plate thickness 2 mm |

| |

| Plate thickness 2,5 mm |

| |

| Plate thickness 3 t/m 4 mm |

| |

| Plate thickness 5 mm |

| |

| Plate thickness 6 mm |

| |

| Plate thickness 8 mm |

| |

| Plate thickness 10 mm |

| |

Holes with a diameter that are too small to cut, are marked. In practice, this means either a small hole or a marking point to indicate the position of the hole.

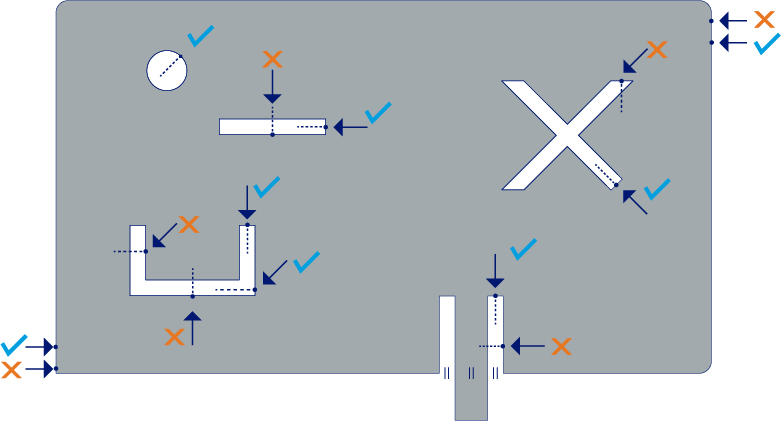

Starting points can be specified in Sophia®. 247TailorSteel determines the position if the starting points have not been specified.

The starting point must be drawn at least 3 mm outside of the entity or at the top (see image). A distance of at least 5 mm applies to sheets that are thicker than 10 mm.

When placing the starting point, note that there must be space perpendicular to the starting point for insertion. A starting point must therefore not be placed in the middle of a narrow slot.

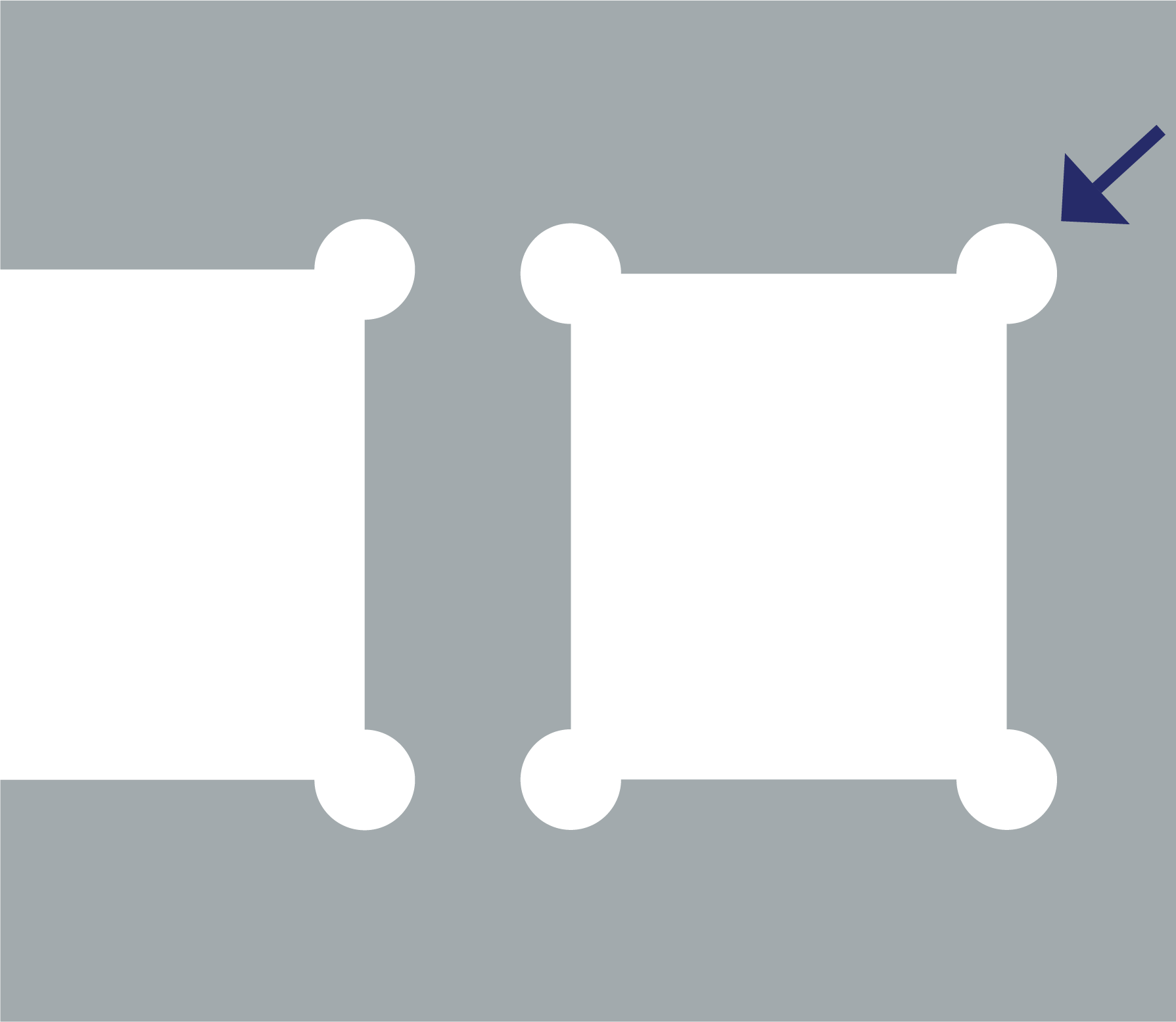

When cutting holes into corners, specific hole diameters are maintained. The table below shows the desired hole diameter according to sheet thickness.

For example, a sheet thickness of 0.5 mm to 3 mm should have a hole diameter of 1 mm. At the opposite end of the spectrum, a sheet thickness of 15 mm to 25 mm should have a hole diameter of 4 mm. See the table for a complete overview.

| Plate thickness | Hole diameter |

|---|---|

| 0.5 t/m 3.0 mm | 1.0 mm |

| 4.0 t/m 6.0 mm | 1.5 mm |

| 8.0 t/m 12.0 mm | 2.0 mm |

| 15.0 t/m 25.0 mm | 4.0 mm |

Edging sharp corners

≤ 3 mm: 0,3 mm

> 3 mm: 0,1 x sheet thickness

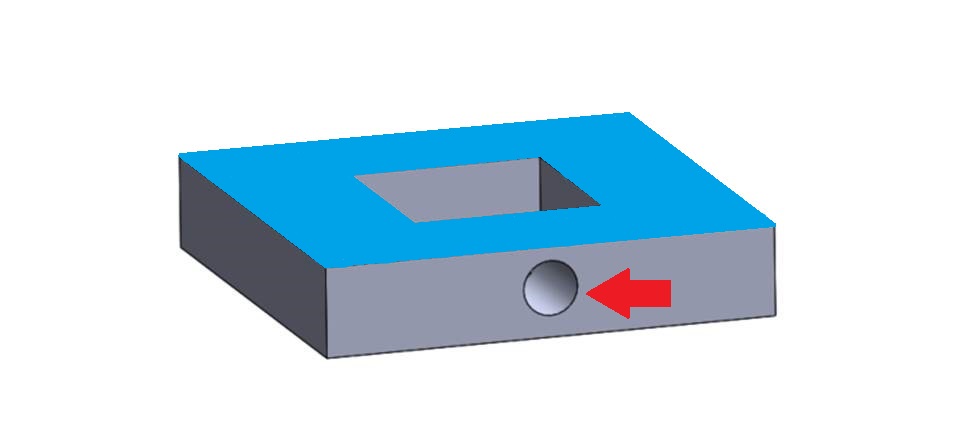

Holes may only be located on the top (blue side) of the product. Holes drawn in the thickness of the material (see illustration) cannot be recognised by Sophia and may cause incorrect hole calculations.

247TailorSteel only engraves functionally, for positioning or identification. Only the upper side of the sheet can be engraved. Foil-coated materials cannot be engraved.

Please refer to STEP and/or DXF/DWG file specifications for character specifications.

Dimensional tolerances of cut contours. Cutting is in accordance with the ISO9013 norm, unless stated otherwise in the table below.

| Work piece thickness (mm) | Allowable tolerances for the range of nominal measurements (mm) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 to 3 | 3 to 10 | 10 to 35 | 35 to 125 | 125 to 315 | 315 to 1000 | 1000 to 2000 | > 2000 | |

| > 0,5 ≤ 1 | ± 0,2 | ± 0,2 | ± 0,2 | ± 0,2 | ± 0,2 | ± 0,3 | ± 0,4 | ± 0,65 |

| > 1 ≤ 3 | ± 0,2 | ± 0,2 | ± 0,2 | ± 0,25 | ± 0,25 | ± 0,35 | ± 0,4 | ± 0,65 |

| > 3 ≤ 6 | ± 0,2 | ± 0,2 | ± 0,25 | ± 0,25 | ± 0,3 | ± 0,4 | ± 0,45 | ± 0,7 |

| > 6 ≤ 10 | - | ± 0,25 | ± 0,3 | ± 0,3 | ± 0,35 | ± 0,45 | ± 0,55 | ± 0,75 |

| > 10 ≤ 15 | - | ± 0,3 | ± 0,35 | ± 0,35 | ± 0,45 | ± 0,55 | ± 0, 65 | ± 0,85 |

| > 15 ≤ 20 | - | ± 0,4 | ± 0,4 | ± 0,4 | ± 0,55 | ± 0,75 | ± 0,85 | ± 1,2 |

| > 20 ≤ 25 | - | ± 0,45 | ± 0,45 | ± 0,5 | ± 0,7 | ± 0,9 | ± 1,1 | ± 1,6 |

| Date | Change Type | Description |

|---|---|---|

| 10/10/2017 |

| Page published |

| 23/10/2017 |

| Changed minimal product dimension |

| 06/12/2017 |

| Changed minimal product dimension |

| 11/12/2017 |

| Changed page content |

| 23/08/2018 |

| Added Holes in corners section |

| 16/04/2019 |

| Several translations and images added to engraving and corners |

| 26/01/2021 |

| Changed hole and dam size |

| 09/06/2023 |

| Changed text about edge finishing |